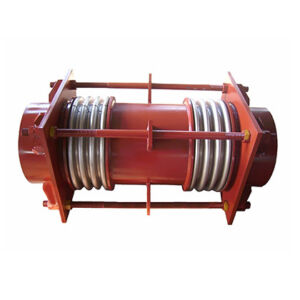

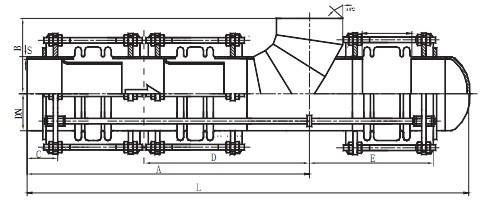

Structural Features

There are two working bellows at the front (channel end) of the curved pipe pressure-balanced expansion joint, and a balance bellows at the rear (balance end). When the bending pipe section produces lateral displacement, the spherical nut wire on the big tie rod rotates around the spherical washer. At the same time, the big tie rod bears the internal pressure thrust. The two bellows at the channel end of the compensator can compensate for the lateral displacement of the curved pipe section, and the balanced bellows at the balance end can compensate for the axial displacement of the straight pipe section.

The curved pipe pressure balance compensator is mainly used to absorb the combined axial and lateral displacement and balance the pressure thrust of the bellows. The compensator is a bellows structure, which is composed of pressure balance corrugations and compensation corrugations. The pressure of the corrugation compensator is balanced by the pressure balance corrugations to relieve the thrust of the compensator and the pipeline. The curved pipe pressure balance expansion joint fundamentally solves the thrust problem of the blind plate force on the fixed bracket, thereby simplifying the design and construction of the fixed bracket and reducing the project cost. The pressure balance compensator can compensate the axial displacement in the pipeline system, and the internal pressure thrust is balanced by itself. This product is used in high-position pipelines where fixed brackets are not suitable.

● Material of Bellows: SUS 304(SUS 321 and SUS316L are also available)

● Nominal Diameter: DN300-DN2000

● Working Pressure: 0.01Mpa-0.6Mpa

● Working Temperature: -80℃/+450℃

● Connection: Flange connections or pipe end connection

● Material of Connection: Carbon steel

● Other choices: Inner sleeve, carbon steel, SUS304(SUS 321 and SUS316L are also available)

● Notes: If you have any other requirement, please contact us.